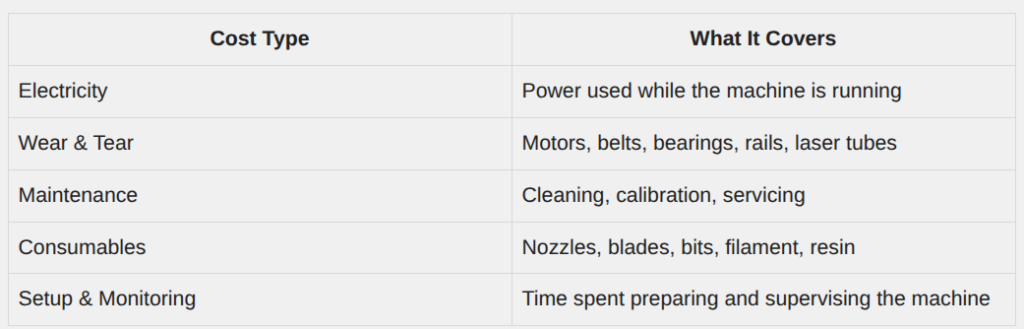

“Machine time” means the actual hours a tool or machine runs to make your products. Its cost is more than just electricity – it includes depreciation, wear-and-tear, maintenance, consumables (like cutting tools or filament), and setup time. Calculating machine time cost gives you an hourly rate for each machine so you can price your work accurately. As Spanflug explains, the machine-hourly rate is literally “the cost of using a machine per hour,” found by dividing all machine-related costs by its running hours. Getting this right ensures you cover expenses and make a profit. Using a calculator can help: try our Universal Machine Time Cost Calculator to plug in your numbers and get an instant rate.

What Is Machine Time Cost And Why Calculate it?

Pricing jobs by guesswork can leave money on the table. In manufacturing (and crafting), machine time is often the biggest cost driver. For example, Fortune Laser notes that “the single most important factor” in laser-cut pricing is **machine time**, not material size. If you underestimate machine costs, you undercharge and lose profit. Spanflug stresses that calculating an accurate machine-hourly rate is crucial for correct quotes and profitable orders. By breaking out machine costs, you avoid hidden losses (for example, paying electricity bills or replacing parts out of pocket instead of charging clients). In short, charging a precise rate prevents underpricing and helps you run a sustainable business.

Components of Machine Time Cost

- Electricity and Energy: Every machine uses power. A small 3D printer might draw 50–150 watts, costing only about $0.01–$0.02 per hour, while a large CNC machine with vacuum tables can be ~$2/hour. Even idle machines use standby power. Include electricity by multiplying the machine’s wattage by your electricity rate. For example, if a laser cutter is 500 W and you pay $0.15/kWh, it costs ~$0.075 per running hour.

- Depreciation & Wear:** Equipment wears out over time. Include a depreciation cost: e.g. a $5,000 machine used 5,000 hours is $1/hour in depreciation. Also add routine maintenance costs (bearing replacements, lubrication, etc.) and periodic overhauls. For laser cutters, Rabbit Laser recommends adding a bit each hour for future tube and lens replacements. Over the life of the machine, these add real expense.

Laser Cutters (CO₂ & Diode)

Laser machines (CO₂ or diode) burn material with a beam. In addition to electricity, their costs include tube/glass lifetimes, mirrors/lenses, and cooling. CO₂ lasers are powerful but less energy-efficient (~10–20%), whereas diode lasers often run at 30–50% efficiency. Diode modules also last much longer (often ~50,000 hours) and don’t require gas tubes, while CO₂ cutters need periodic tube replacements. For both, calculate tube life: e.g. a 100W CO₂ tube might be rated for 5,000 hours; if it costs $500 to replace, add $0.10/hour. Include small fees for lens/mirror replacements. Electricity can be high: a 100W laser and its cooling pump might draw 500–1,500W total, so at $0.15/kWh that’s roughly $0.08–$0.23 per laser hour. In practice, manufacturers often charge by laser time: Fortune Laser emphasizes that the quote formula’s largest factor is “machine time,” multiplying an hourly laser rate by hours of cutting. By crunching all these inputs into an hourly rate, your pricing covers each cut’s true cost.

3D Printers (FDM & Resin)

3D printers (filament FDM or liquid resin) also have distinct costs. FDM machines use plastic filament (typically $20–$30/kg for PLA, $25–$40/kg for ABS) and motors/heaters drawing ~50–150W (very low electricity costs). For example, printing a 15-gram model (like a small figurine) on PLA ($20/kg) uses ~$0.30 in material, and only a few cents of power. Eufy’s calculator example shows one Benchy model cost about $0.31 to print (including $0.30 material + $0.01 power). Don’t forget wear: replace nozzles and keep your belts and rods lubricated (a few dollars every few months). Resin printers have similar overhead plus the resin (usually $50–$70/kg standard, $80–$200/kg specialty) and cleaning supplies (alcohol, gloves) plus curing time. The slow speeds of resin prints mean machine hours add up quickly. In summary, build your 3D printer hourly rate by summing electricity, filament/resin cost per hour, and amortized machine wear. (You can use formulas like “electricity + material + wear and tear + other costs” per hour.)

CNC Routers

CNC routers (for wood, plastic, or metal) are generally more power-hungry. A hobby CNC might draw 500–1,500W, while a professional spindle and vacuum table can use several kilowatts. As CNCSourced notes, even a powerful CNC might cost around $2 per hour in electricity. Also include cutting tools: router bits and end mills wear out (for example, carbide bits might last hundreds of hours and cost $10–$30 each). Amortize these: if a bit costs $30 and lasts 300 hours, that’s $0.10/hour extra. Machine depreciation is also significant: small desktop CNCs ($2,000–$5,000) vs industrial ($20,000+). Use Spanflug’s approach: divide your machine’s cost by its effective hours and add maintenance/insurance. In practice, many CNC shops charge $30–$100+ per hour to cover all this. By breaking out power, tooling, and machine wear, you set a rate that covers true costs.

Commercial CNC machines (like metal-cutting mill) have high running costs, so users must calculate an hourly rate that covers power and tooling wear.

Woodworking Tools

Even manual woodworking machines (table saws, planers, routers, sanders) have operating costs. They draw 500–2,000W when cutting, and their blades/bits wear out. For example, a $100 table-saw blade might last 100–200 hours, so add ~$0.50–$1 per saw-hour for blade replacement. Dust collectors and air compressors draw additional power. Setup time (adjusting fences, safe-on) should be considered too. In smaller shops, overhead like shop rent and electricity is spread over projects; Rabbit Laser’s example would similarly break monthly shop expenses into each job. The key point is that woodworking equipment uses the same formula: add up electricity, blade wear, maintenance, etc., then divide by hours to get a per-hour rate. This ensures that, like CNC and lasers, every board cut covers its costs. (See Spanflug: “manufacturing costs” include average power and tool costs for all machine tools, even 3D printers and CNCs.)

Even hand tools and woodworking machines incur costs (blades, electricity). All workshop machinery should be costed out by the same method.

Machine Time vs. Labor Cost

Note: “machine time cost” covers only the machine’s expenses, not your personal labor. You should charge your own hourly wage or salary on top of the machine rate. Spanflug describes a “manufacturing hourly rate” that separately includes machine costs and labor costs. In other words, if your machine rate is $10/hr and your labor rate is $30/hr, you’d charge $40/hr of production time. Keeping them separate ensures you are paid for both the machine and your work. Many crafters forget this and end up underpricing. By calculating machine time cost accurately, you can then add your well-earned wage on top.

Consistent Method for All Machines

The beauty of this system is that it works for any equipment – from lasers to lathes. All machines have fixed costs (purchase price, maintenance) and variable costs (power, consumables). Spanflug’s machine-rate calculator explicitly supports everything from lathes, mills, drills and saws to even FDM and SLA 3D printers. The formulas are the same: total up the expenses and divide by run-time. By treating all tools the same way, you simplify your pricing strategy. Whether it’s a diode laser or a dust collector, following these steps ensures no hidden costs slip through. In practice, this means a universal calculator or spreadsheet can handle any machine – hence our Universal Machine Time Cost Calculator is designed to cover all tool types.

What Costs Are Included in Machine Time Cost?

Calculate Your Machine Time Cost Automatically

I built a universal machine time cost calculator because I was tired of guessing. It works for lasers, 3D printers, CNC machines, and woodworking tools.

Use the Universal Machine Time Cost Calculator

Conclusion

Accurately calculating machine time cost is essential for a profitable craft business. It ensures every minute your machine runs is paid for, preventing losses. By breaking costs into electricity, wear-and-tear, consumables, maintenance, and setup (and adding your labor rate separately), you create fair and profitable pricing. Use a precise formula or tool to do the math. And remember: guessing is risky – a calculated hourly rate based on real data keeps your craft business healthy. Ready to streamline your pricing? Try our Universal Machine Time Cost Calculator to quickly determine your machines’ costs and maximize your profit.

Machine Time Cost – Frequently Asked Questions

Is machine time cost the same as hourly wage?

No. Machine time cost covers the cost of owning and running a machine. Your personal hourly wage should be added separately.

Do I need a different formula for each machine?

No. All machines follow the same logic. Only the input values change.

Should setup time be included in machine time cost?

Yes. Setup and monitoring time are part of machine usage and should be included.